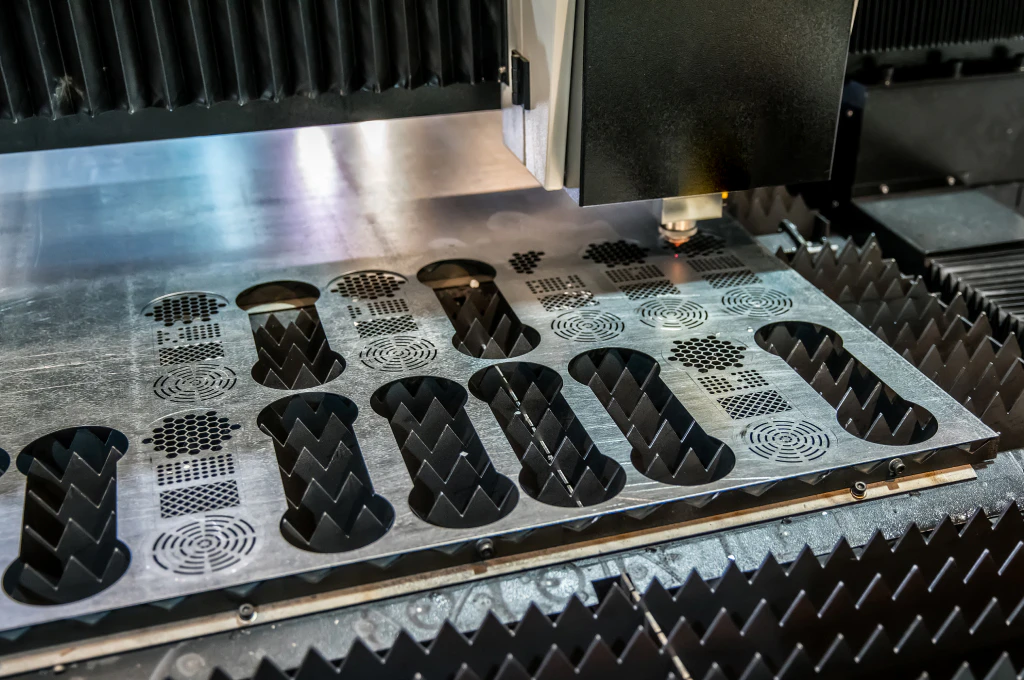

CNC laser cutting machines are used to cut materials such as stainless steel, sheet metal or aluminum that will take a long time to be made by human hands. With this method, the metal can be formed faster and with higher quality.

CNC laser cutting technique is also used at the points where precision work is required. Since the error rate in laser cutting is almost zero, critical parts can be manufactured with CNC machines. Those looking for a guarantee in their work and those who like to work without risk may prefer the laser cutting technique.

So what exactly is CNC laser cutting technique? Where to use?

What is CNC Laser Cutting?

In its simplest form, CNC laser can be explained as directing a powerful laser beam with optical glasses and thus cutting the metal in the desired shape. Laser optics and CNC machine pre-loaded codes guide both the metal and the laser beam. Thus, various motifs can be embroidered on the material, and the metal can be cut perfectly and made ready for use.

At this point, it would be good to explain how laser beams work. The laser beam, which is the most important component of the CNC laser cutting method, is produced in a closed environment in the machine. During production, electrical resonances are used and the beam is exposed. Apart from resonance, help can be obtained from lamps suitable for the purpose.

Energy begins to accumulate in the beam and at a certain point, the beam is activated with the power given by this energy. After directing the beam to the optical surface, it goes to the lenses. The beam reflected from the lenses finally focuses on the material.

After the laser beams contact the metal, the material melts or evaporates from the contact points according to the chosen method. In addition, metal can be cut by thermal stretching, silicon fluidity or reactive cutting (combustion) methods.

Let's take a closer look at these methods:

Thermal Stretching: The laser beam heats the metal and causes expansion. Thus, cracks form on the surface and the material is cut.

Silicon Fluidity: Cutting the material using electronic chips is called silicon fluidity.

Reactive Cutting (Combustion): It is generally preferred for cutting thick steels. Better efficiency can be obtained while saving the laser beam used.

In the final stage, a special gas is sprayed by the machine and the part separated by the beam is ejected by gas power.

What are the Types of Laser Cutting CNC?

The types of laser CNC machines are linked to the type and requirements of the hardware integrated laser. Of course, the laser equipment used also changes the usage area of the product. In general, facilities equipped with Laser Cutting CNC equipment have almost all of these bits and can use different configurations for every need.

Laser Cutting CNC Types

CO2 Laser Cutting Machine

The CO2 Laser Cutting Machine, which produces beams by reacting carbon dioxide gas with high voltage electricity, can cut materials with less density, while operating at a low energy consumption level. For example, plastic materials, wood, glass and similar materials can be cut and shaped with this type of laser.

Neodymium Laser Cutting Machine

The laser cutting cnc machine, in which laser technology is used most powerfully, is the machine in which neodymium lasers are used. It is possible to cut very thick and highly resistant materials with very high intensity laser beams with these equipment. Metals, ceramics and similar dense products are cut with these machines.

Fiber Laser Cutting Machine

Fiber laser cutting machine is a type of laser developed by adding fiber to neodymium technology. This equipment, whose sensitivity can be adjusted finer and whose qualities such as density can be changed, is used more intensively in works that require fine workmanship. This hardware is commonly preferred when working on metal in more detail.

Where is CNC Laser Cutting Used?

Today, CNC laser cutting method is used in many places. The fact that it is a risk-free method and the machine performs the process alone, without the need for another machine, causes CNC laser cutting to be used frequently.

Laser cutting can be used in the following areas:

If there is a pattern that is desired to be embroidered on the material, it can be processed in a flawless and aesthetic way. It provides a great advantage especially in the production of decoration products.

It may be desired to mark the metal material. The brand name/logo can be easily engraved on metal with laser beams.

It is the first choice in cases where mass production is required. Industrial materials can be molded by laser cutting. Especially in the automotive sector, CNC laser cutting method is used in the production of spare parts.

If 3D cutting is required, excellent products can be obtained with CNC laser. Considering how important 3D material production is today, the importance of laser cutting will also emerge.

CNC machine can be used in the production of parts of other machines. Thus, machine parts are produced with low cost and high efficiency.

Laser cutting is also used in the production of signage. Aesthetic and robust signs can be completed and delivered in a short time thanks to CNC laser.

CNC laser cutting technique has a great place in the manufacture of tools needed in the medical field.

It is preferred in the production of parts that need to be sealed, as there is no margin of error.

Based on this, it is not correct to limit the use of Laser Cutting CNC machine to any industry sector. It is possible to use Laser CNC in every field from the production of hobby products to the automotive industry, from the PVC industry to furniture.

Laser Cutting CNC Prices

CNC Laser cutting prices cannot be expressed with a single price policy, considering the features we have mentioned above. Factors such as the quality of the laser used, the type of material, the size and details of the project are the determining factors over laser cutting CNC prices.

To get information about the price of the application you need, for example, you can contact our company, if you wish, you can review the information on our Laser Cutting CNC page. Our company offers comprehensive solutions for all your needs and supports your industrial applications at the best prices.

Türkçe

Türkçe

العربية

العربية